|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Aqualine ~ Suppliers of quality swimming pools in Paphos, Cyprus | ||||||||||||||

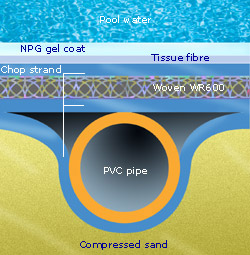

| The six layers of construction

~ NPG Gel Coat Application. This is a resin-rich surface applied for its water, chemical and UV resistance. The mould is sprayed with the gel coat to closely achieve the perfect thickness of 28mm – too thick and it will crack, too thin and it will bend. Our operators gauge their gel coat in over 20 distinct locations, and we record this as part of the quality report. It is this extra layer, along with the NPG colouring, that gives each pool its solid, satin-smooth finish. ~ Derekane Epoxy-Vinyl Ester with Tissue Fibre. This layer prevents any cracks or bubbles from forming in the gel coat. ~ 450gm Chop Strand Mat Fibre This layer is for strength and durability and, though sometimes omitted by pool manufacturers cutting corners on quality, it is crucial to providing a water and blister barrier for your pool. ~ Woven WR 600 Fibre. This cloth-type material creates a ‘shield of armour’ around your entire pool. It is installed using the same vinyl ester resin as in the previous layer. |

||||||||||||||

| ~ 2nd application of 450gm Chop Strand Mat Fibre . Doubling the thickness of this core material increases the strength of the pool shell by 8 times.

~ Bonding PVC pipes are attached vertically and horizontally with bonding paste and laminated with chop strand mat fibre. This ensures that the shell reinforces itself with the compacted sand when installed. |

||||||||||||||

|

|

|||||||||||||

|

||||||||||||||

| < Designed and built to last | ||||||||||||||

| Surface textures combine ultra smooth sides with non-slip areas underfoot. | ||||||||||||||